The application of the new integrated multi-function analyzer BioProfile FLEX automated sampling system

The results of studies of mammalian cell culture during the fermentation process show that the system significantly reduces manual labour and associated measurement errors. The measurement process takes place online without any interruption/disturbances of fermentation. The automation of monitoring processes increase the biomass of cultures of cells allows to obtain more reliable results that will not depend on the operator. In addition, the BioProfile FLEX analyzers have the ability to set the feedback system with the controller of the fermenter, allowing to program, for example, the flow of feed not only on the content of oxygen in the culture medium, but also on the concentration of glucose or other nutrient concentrations of the substrates.

Fermentation-based mammalian cell culture is widely used for industrial production of therapeutic proteins. Monitoring of Cell cultures is essential for development, optimization and management of productive and sustainable cultivation processes. As a rule, parameters such as pH, dissolved oxygen and temperature can be monitored by means of sensors of direct action (which are part of the fermenter/bioreactor). The possibility of controlling these parameters allows to carry out reliable, reproducible cycles of fermentation, and also scale biotechnological processes.

Other important parameters of the fermentation, are still typically monitored via manual sampling and using several off-line analyzers or routine methods of analysis. Some of these parameters are used in the process of operation of the fermenter. For example, the flow into the fermenter, the nutrient medium is carried out according to the results of the analysis of the culture medium.

Other parameters such as cell viability, dissolved gases, nutrients, osmotic pressure, and cellular metabolites are monitored as indicators of reproducibility of culture. This information is important for the realization of a biotechnological process and for understanding the impact of cultivation conditions on efficiency, productivity and product quality. Off-line monitoring of important parameters is a time consuming procedure due to manual nature of collecting information from multiple analyzers, and data entry into the controller of the fermenter. A large amount of manual manipulation allows for the possibility of operator error in the process of these actions. In addition, in each sample, selected manually, there is a risk of a breach to the sterile barrier, which could lead to contamination of the culture.

To reduce manual labor involved and increase the reliability of the fermentation process in the last decade, there have been developed various new online monitoring tools of cultivation. Many of these achievements have been successfully applied to systems with cell cultures, including determination of the optical density with the use of capacitive sensors of cell density; near-infrared spectroscopy (NIRS) for the control of various cellular components of culture; flow-injection analysis (FIA) for sample delivery for offline analyzers; online high performance liquid chromatography (HPLC) for monitoring amino acids and other concentrations of metabolites or metabolic products; as well as automated samplers coupled with off-line analyzers such as HPLC. Although NIR spectroscopy is possible, in theory, eliminates the need for off-line mode, but remain significant limitations to the successful industrial application of this technology for monitoring cell culture. They include the establishment of a reliable calibration and data analysis methods that can be implemented in the prescribed manner by the operator without special training, and the development of methods for quantitative evaluation of biomass for mammalian cells.

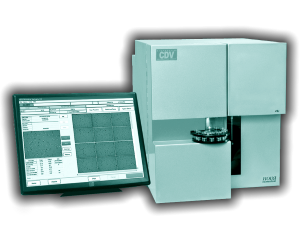

Thus, the need remains in conventional off-line monitoring of cell cultures. The latest innovation in off-line monitoring of cell culture has allowed to create a complex analyzer. The BioProfile FLEX analyzer (NOVA Biomedical) combines the functionality of three off-line analyzers (analyzer, biochemical analyzer, cell counting, vapor-pressure osmometer) in a single device. The analyzer has a modular design, including the modules of gases/electrolytes, nutrients/metabolites, cell density/viability, and osmoticeski module. Gas/electrolyte module and the module of nutrients/metabolites using ion-selective electrodes, potentiometry, amperometry, and fermentation, depending on the biosensors.

Module density/cell viability was developed by NOVA Biomedical for cell counting and assessment of viability based on traditional triptofanom blue exclusion method. First, the sample of cells is mixed with triptofanom blue, and the mixture is incubated so that the dead cells absorb the blue tryptophanby. The sample is then deposited on the translucent bottom of a flow cell. The flow cell is moved to a fixed microscope objective using a precision motion control system, high-resolution images. Cell count and viability is determined by image processing based on user defined constraints such as living/dead cells, the brightness and the average size of the cells.

Each module can be selected individually, using all BioProfile FLEX modules require only 1 ml sample of the culture fluid, and 7.5 min for analyses. Results and user the exported electronically in spreadsheet format.

Although integrated analyzer in data entry orders is partly manual labor, but only the new unique automatic sampling system developed specifically for the BioProfile Flex (NOVA Biomedical), completely eliminates manual labor.

Numerous studies show the successful application of a new integrated multi-function analyzer and automatic sampling system for monitoring mammalian cell culture. The obtained results show that the system has the potential to reduce manual effort and associated errors. The measurement process can occur online without any interruption/disturbances of fermentation.

Authors: Ducommun, P., Bolzonella, I., Rhiel, M., Pugeaud, P., and von Stockar, U. (2001). On-Line Determination of Animal Cell Concentration. Bioengineering and Biotechnology, 72 (5) 515-522. Feng, L., Zhou, J. X., Yang, X., Tressel, T., and Lee, B. (2005). Current Therapeutic Antibody Production and Process Optimization. Bioprocessing Journal, September/October 2005 23-30. Tucker, K. G., Chalder,S., Al-Rubeai, M., and Thomas, C. R. (1994). Measurement of hybridoma cell number, viability, and morphology using full automated image analysis. Enzyme Microbial Technology, 16 29-35.