Fermentation. General information.

The two General aims of the study the manufacturing process of biotherapeutic medicines are reducing research time and improving understanding of the processes occurring in the fermenter during cultivation of the cells. Both of these goals require increased bandwidth in the work of the biotechnology lab. One of the ways to increase the productivity of research in the field of biotechnological production is the increase in the number of bioreactors (fermenters) and/or increasing the frequency of sampling from the bioreactor; however, these approaches are associated with higher levels of expenditure on research associated, primarily, with an increase of laboratory personnel. Thus, the automation of online sampling of the fermenter is the only solution to increase the number of biotechnological experiments and improve their performance. In early 2009, an automatic sampler (autosampler) FLEX manufacturing NOVA Biomedical was put into biotechnology market. Pfizer has acquired a commercial unit and conducted comprehensive testing to verify whether it meets the three key requirements for the successful implementation of our vision of the “laboratory of the future”.

These are the three main requirements:

1) maintenance of sterility in the bioreactor/fermenter for an extended period of time; up to 3 weeks fueled culture;

2) interaction with various analytical tools;

3) maintaining the accuracy of cell cultivation (e.g., no dilution, no loss of gas components during sample processing).

In the present work we showed that autosampler FLEX meets all three requirements.

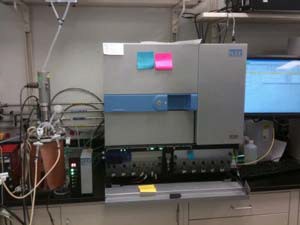

Sampler NOVA Biomedical FLEX can be used for taking samples from fermenters out of 9 based on a user defined program. The sample fed to the measuring unit FLEX analyzer, which analyzes the cultural liquid of the following parameters: concentration of metabolites, gases, electrolytes, density of viable cells and serum osmolality.

Materials and methods

- Recombinant CHO cell lines grown in defined chemical media with addition of certain chemical nutrients.

- 1 l Applikon fermenter.

- FLEX automatic sampler takes samples of their 2 fermenters and transmits them to the measuring unit of the analyzer FLEX.

- Data obtained from the FLEX autosampler were compared with data taken from the reactor manually and carried out their statistical analysis.

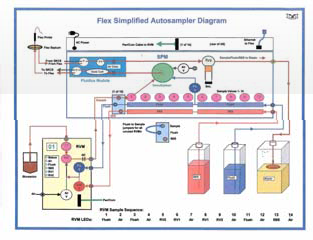

- Feks Autosampler Scheme

The laboratory setup Ports and connections

Insights

The automatic sampling system (autosampler) FLEX meets all three requirements set out in the introduction:

- Successfully meet the requirements of sterility.

- The results of the analysis of concentration of gases and metabolites: ∆PH ≤0.035, ∆PCO2 ≤10%, ∆Glucose ≤10%, ∆Lactate ≤10%

- The results of the analysis cells: ∆Viable Cells ≤10%, ∆Viability ≤2%

- The automatic sampling system (autosampler) FLEX can be used to provide a deeper understanding of the processes taking place during fermentation in real time while minimizing working time. Reliable automatic sampling system is the cornerstone of the further application of process analytical technology in biotechnology.

Authors:

Kavi Mehta, Erwin Y. Yu, Susan Casnocha, BioTherapeutics Pharm Sci, Pfizer Inc, St. Louis, MO 63017